Transverse leaf spring

√ High-quality raw materials: 60Si2Mn/65Mn

√ OE Number: WG9516523010

√ Length: customizable according to customer’s demands

√ Painting and character stamping: performing painting and character stamping according to customers’ demands

√ Logos: customizable as required by customers

Description

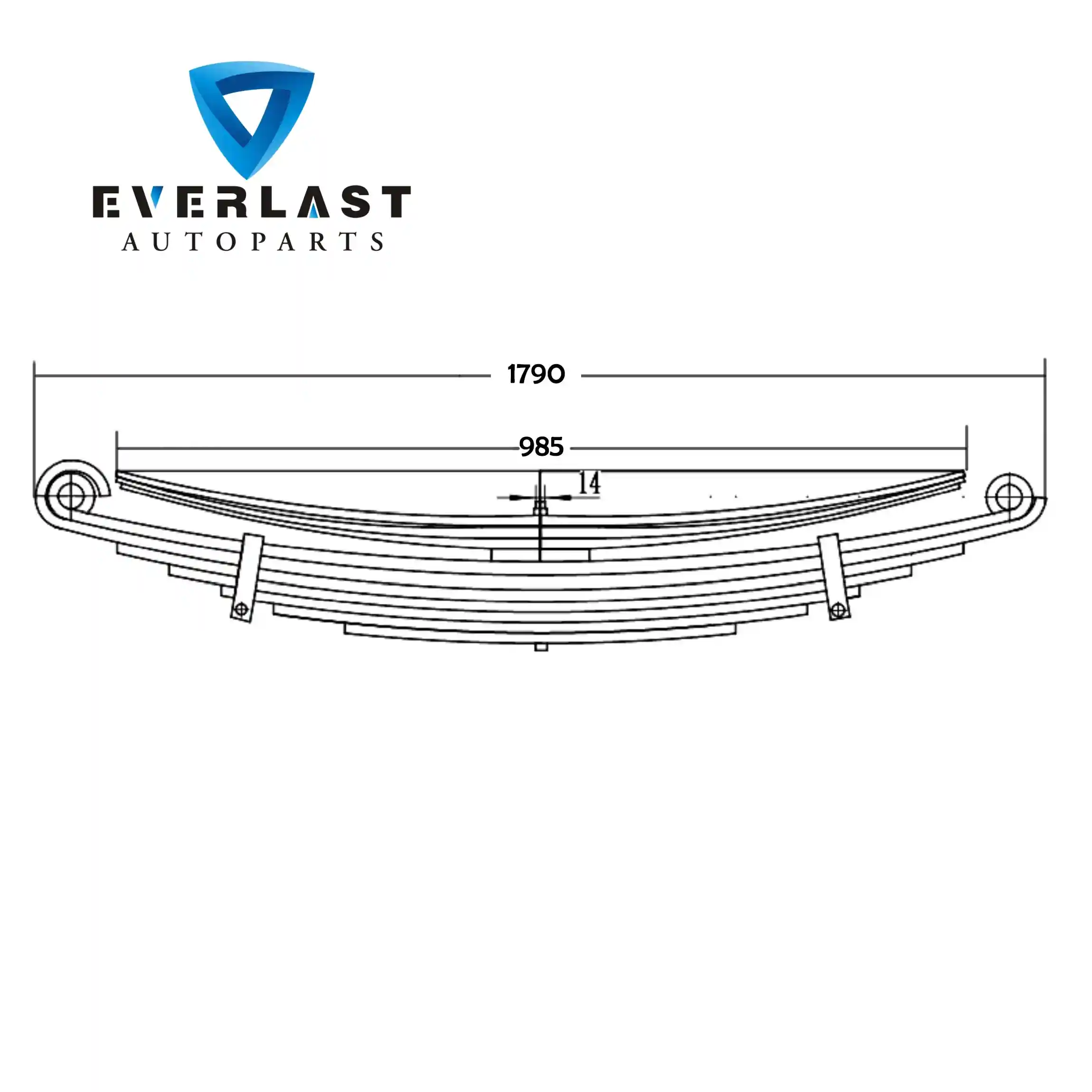

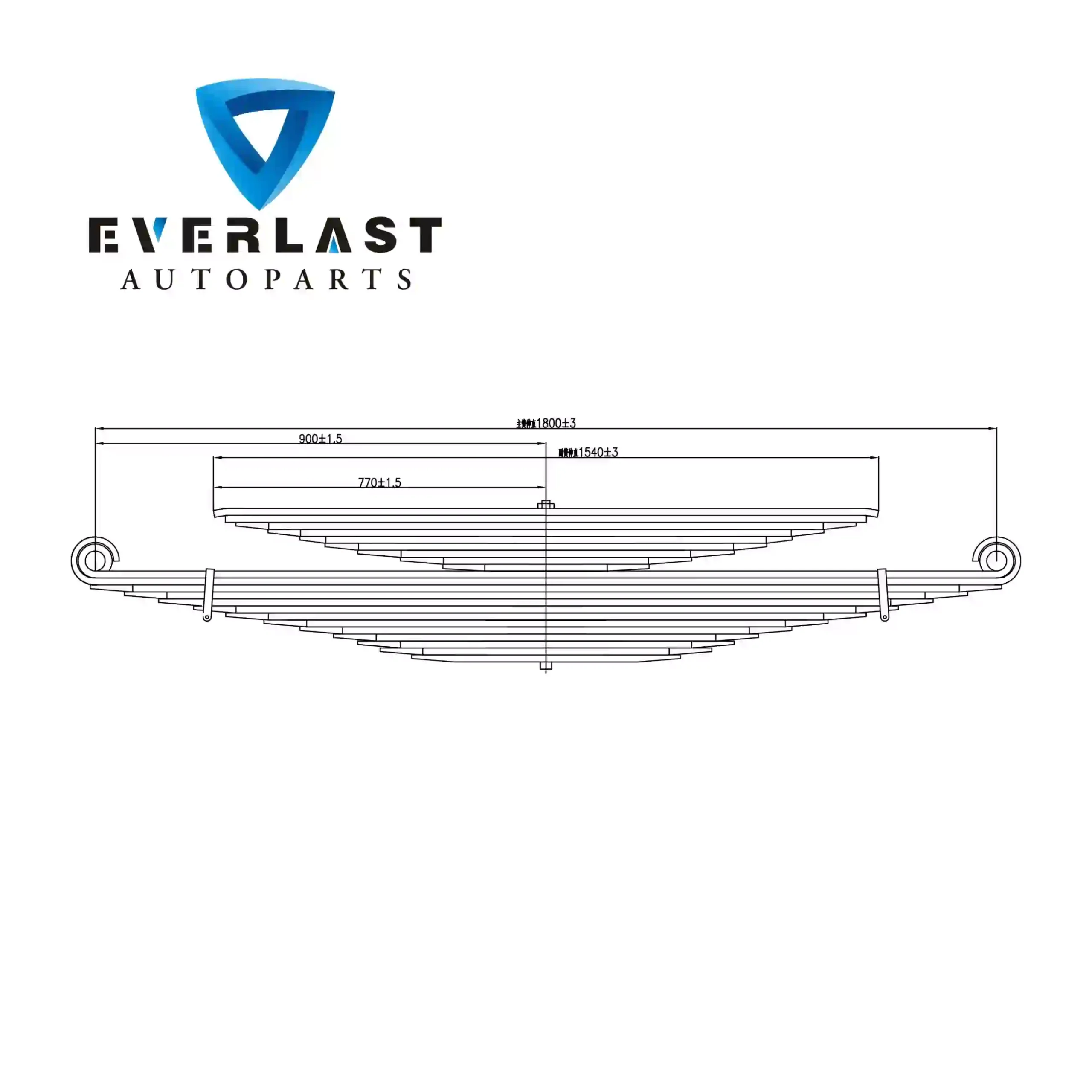

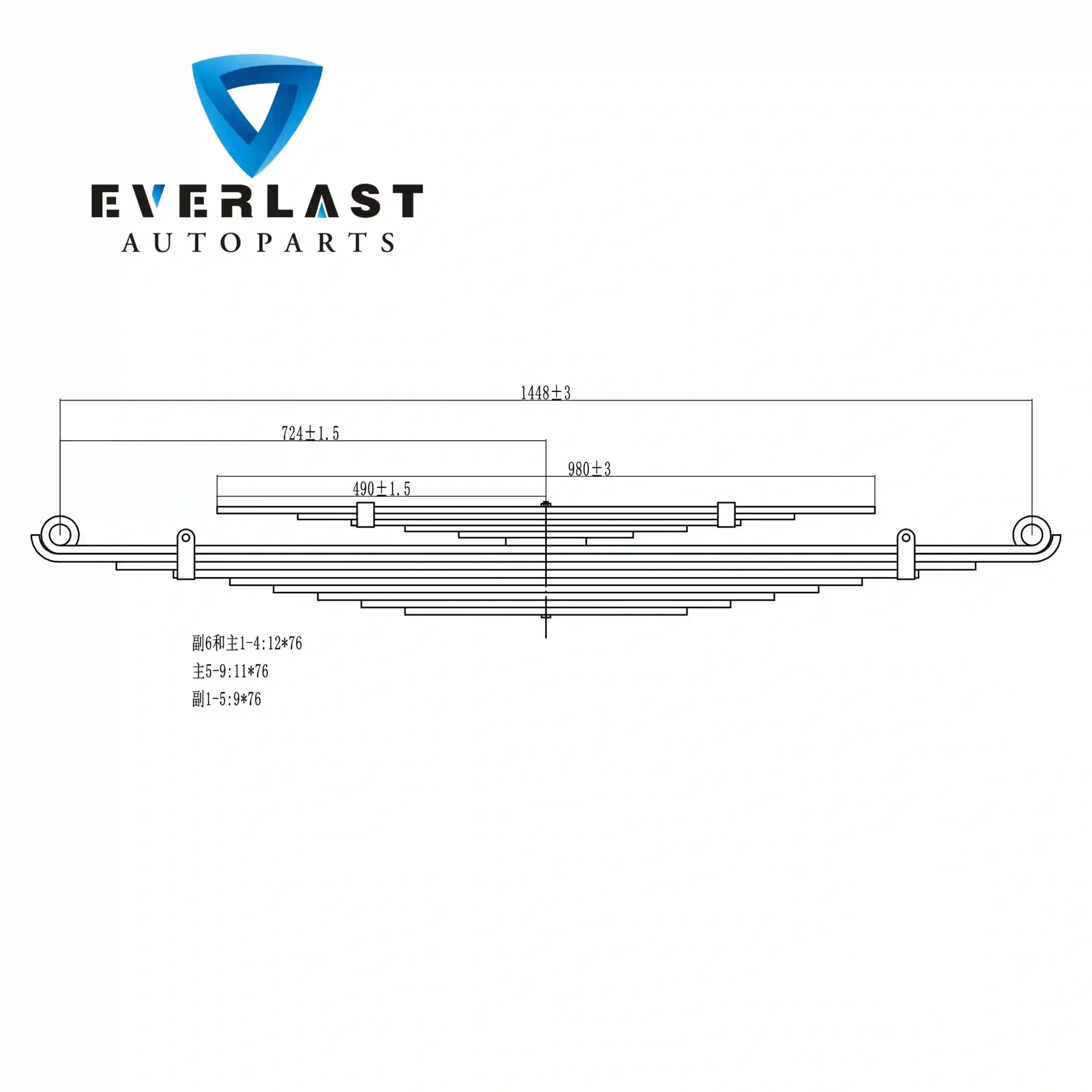

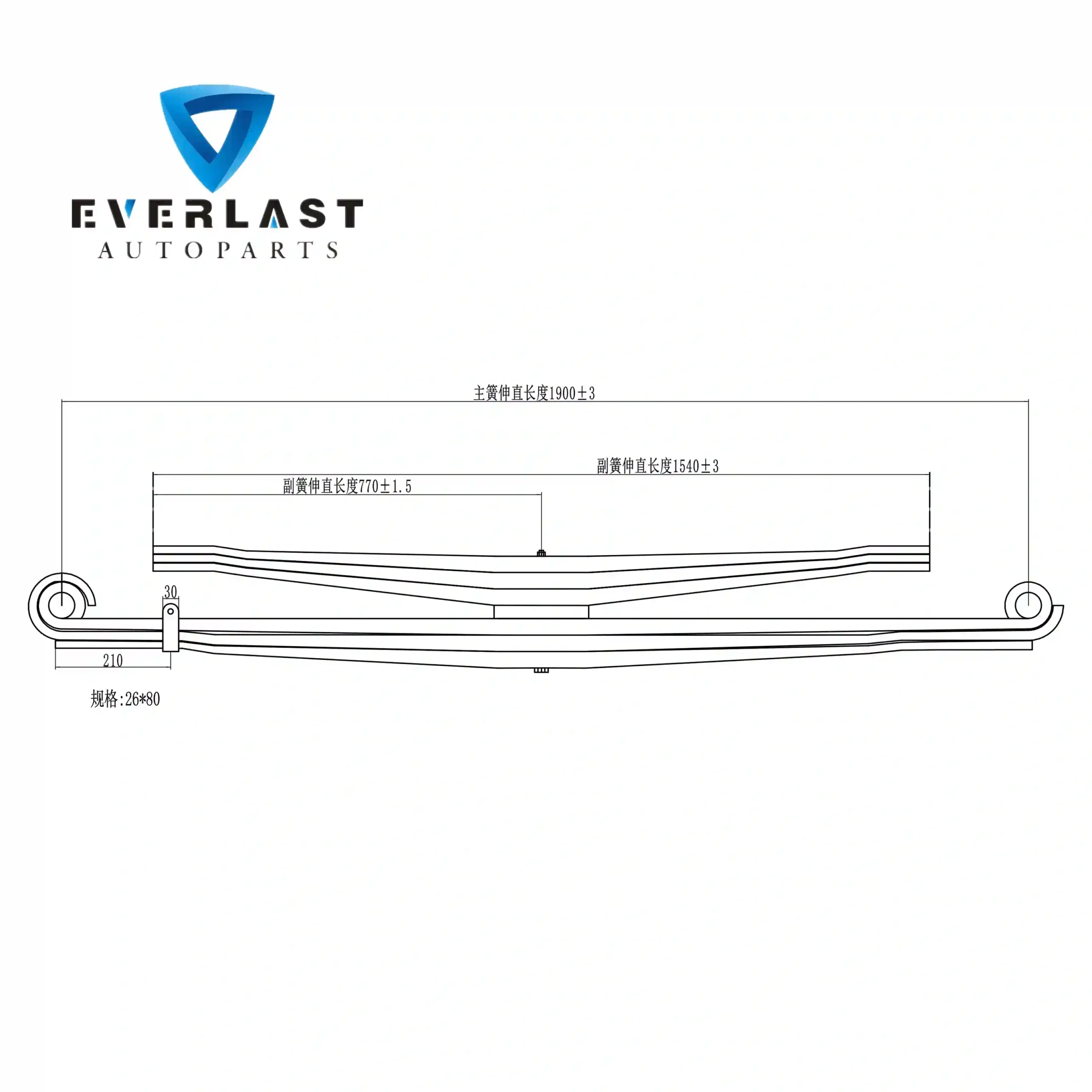

Specification: 14*90

Material: 60Si2Mn/65Mn

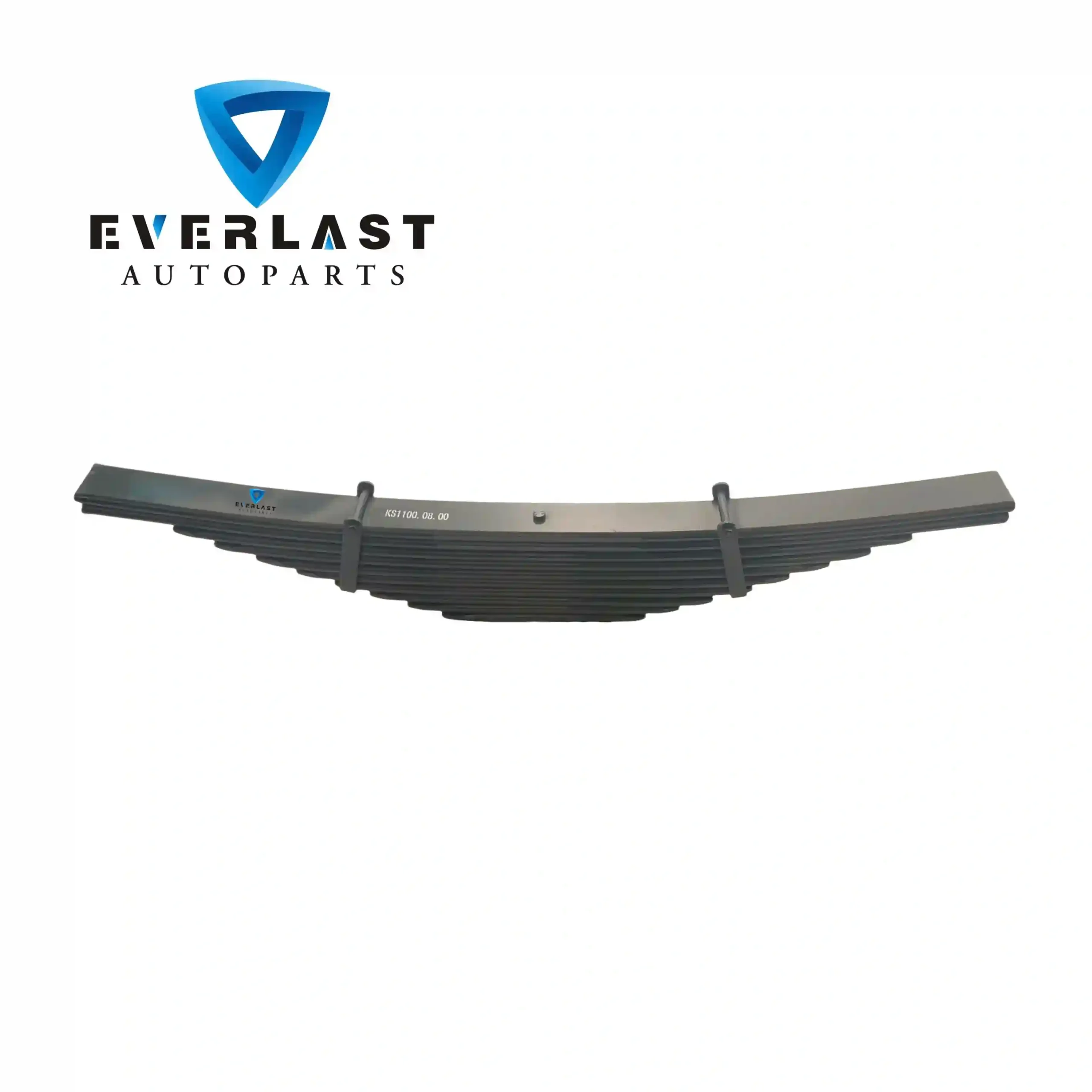

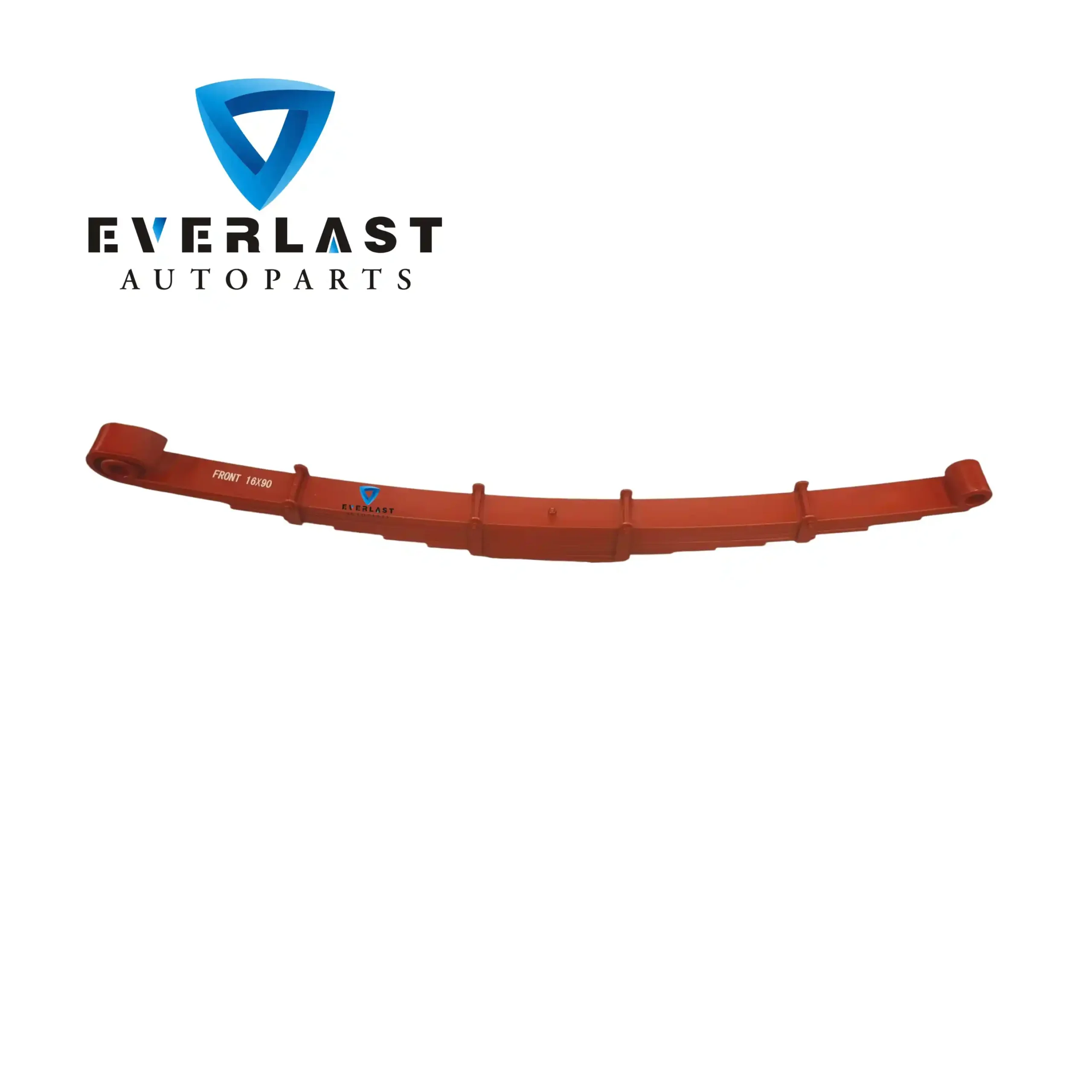

The leaf spring assembly WG9516523010 is composed of one central bolt, two bimetallic bushings, and two clip plates. The assembly is formed by stacking a total of nine spring steel leaves. The production process of this leaf spring assembly includes raw material blanking, eye rolling, quenching, shot blasting, and other processes to form a stacked alloy spring leaf combination with unequal lengths and unequal curvatures for multiple leaves, which constitutes an elastic beam with approximately equal strength. After mounted, both ends of the assembly bend upward naturally, it buffers road impacts through deformation and transmits loads, and has both shock absorption and guiding force transmission functions. As for spring eyes of a main leaf, they are treated as structurally weak points, and the design of rolling the eyes at the ends of the second leaf and reserving of gaps are often adopted to enhance its strength. When arranged longitudinally, it can effectively coordinate the relative displacement between an axle and the frame; and when bearing vertical loads, it achieves progressive stiffness characteristics through the coordinated deformation of the spring leaves. This model of assembly exhibits excellent performance in normal fatigue resistance tests and complies with the standards of GB/T 19844-2005 and ISO 9001.

When the impact force from bumpy roads is transmitted to wheels, the steel plates deform to play a role in buffering and shock absorption. When arranged longitudinally, it also has the function of guiding force transmission, and its structure is simple.

.webp)

-scaled.webp)