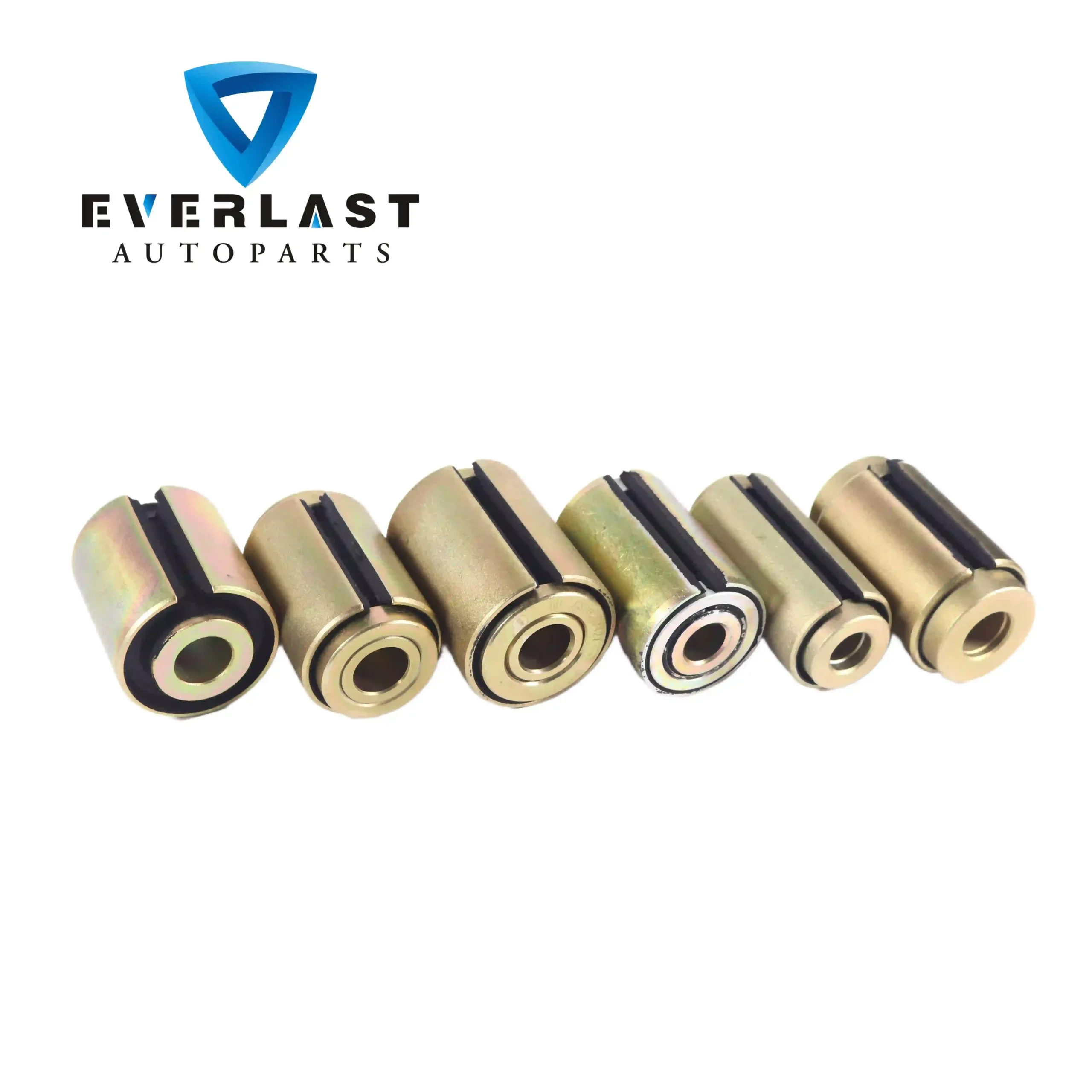

bushings for suspension

√ Strong design capability of our engineer teams

√ Automated production line and intelligent warehousing system in factories

√ Equipped with high-precision detection devices

Description

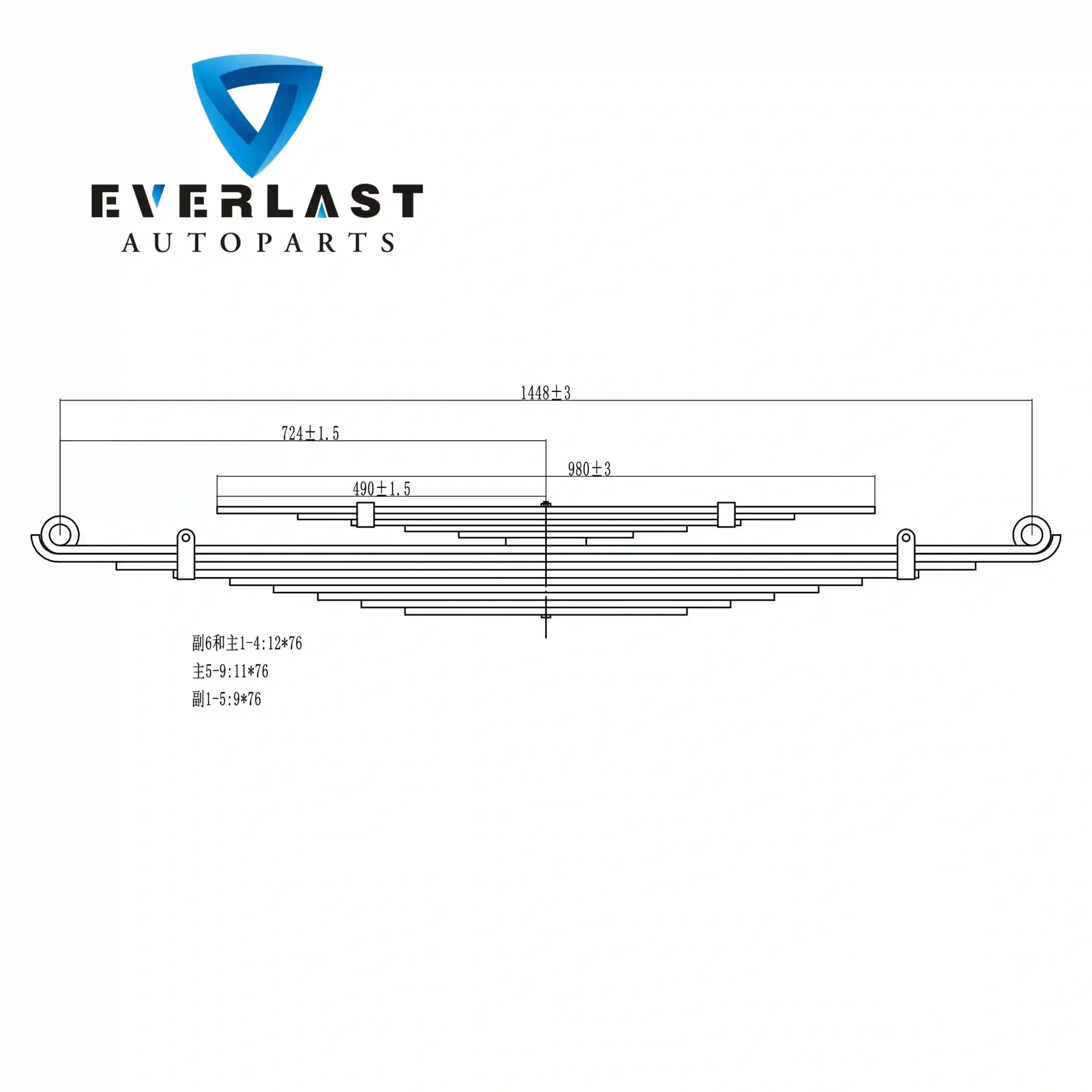

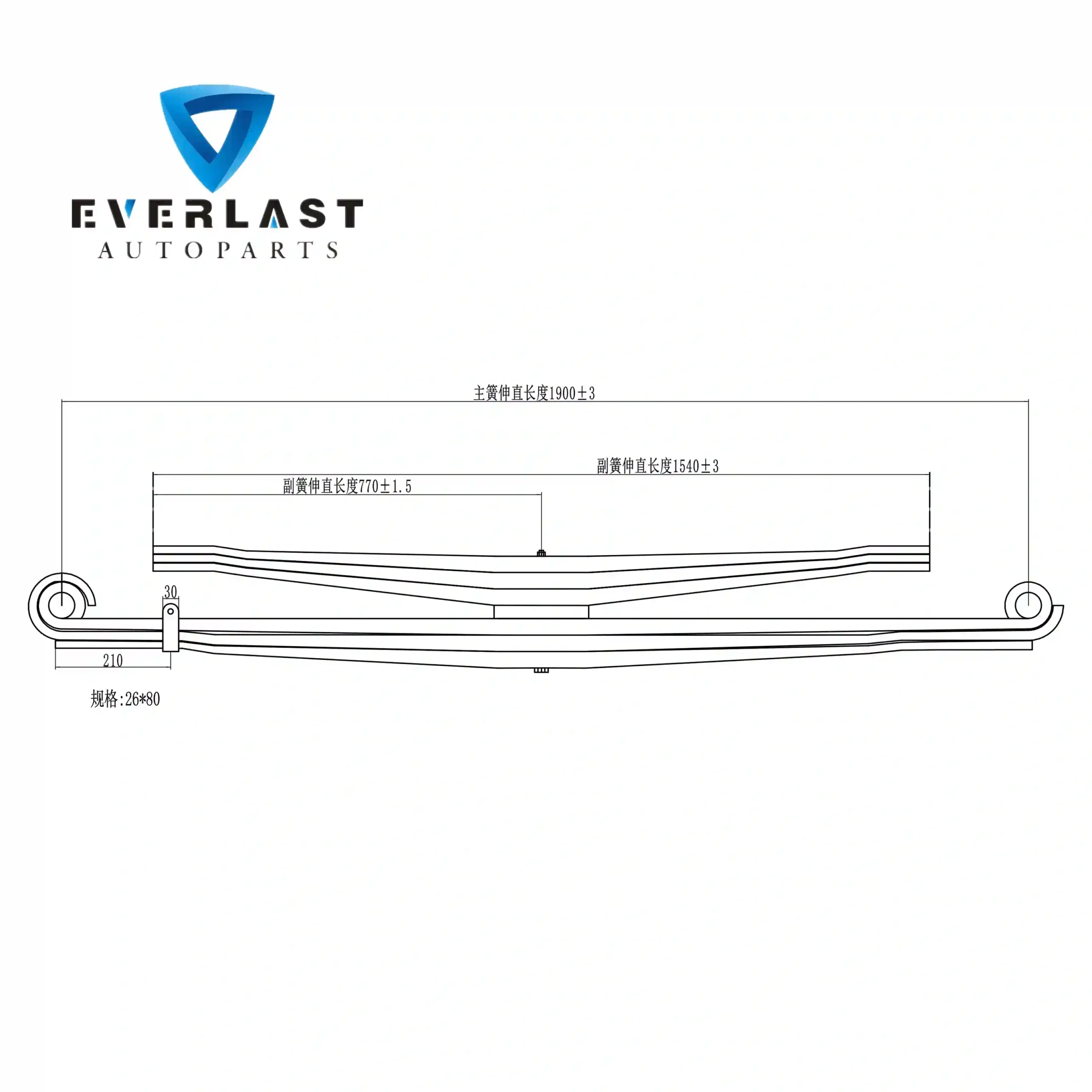

Specification:

Material: steel, rubber

When replacing traditional one-piece bushings, the entire assembly usually needs to be completely removed, and a large press is even required to press out the old bushing and press in the new one, making the whole process time-consuming and labor-intensive. However, this heavy-duty truck split bushing, with its unique split design, can be directly installed and removed from the side face. Maintenance workers only need to loosen the bolts to easily take off the old bushing, put the new bushing in place by hand, and then tighten the bolts. The entire replacement process may only take 15-30 minutes.

The significant reduction in maintenance time directly leads to a substantial decrease in labor costs. Fleet operators do not need to pay for several hours of labor just to replace a single bushing. The split bushing can shorten maintenance time from half a day or even a full day to less than an hour, allowing vehicles to return to operation more quickly and greatly reducing the loss of economic benefits caused by maintenance.

This high-quality split bushing is pre-filled with long-lasting grease before leaving the factory, ensuring that the bushing is in a good lubrication condition from the start and reducing the risk of initial wear.

For fleet operators and vehicle owners who prioritize operational efficiency, choosing this high-quality split bushing is a very valuable investment.

.webp)

-scaled.webp)