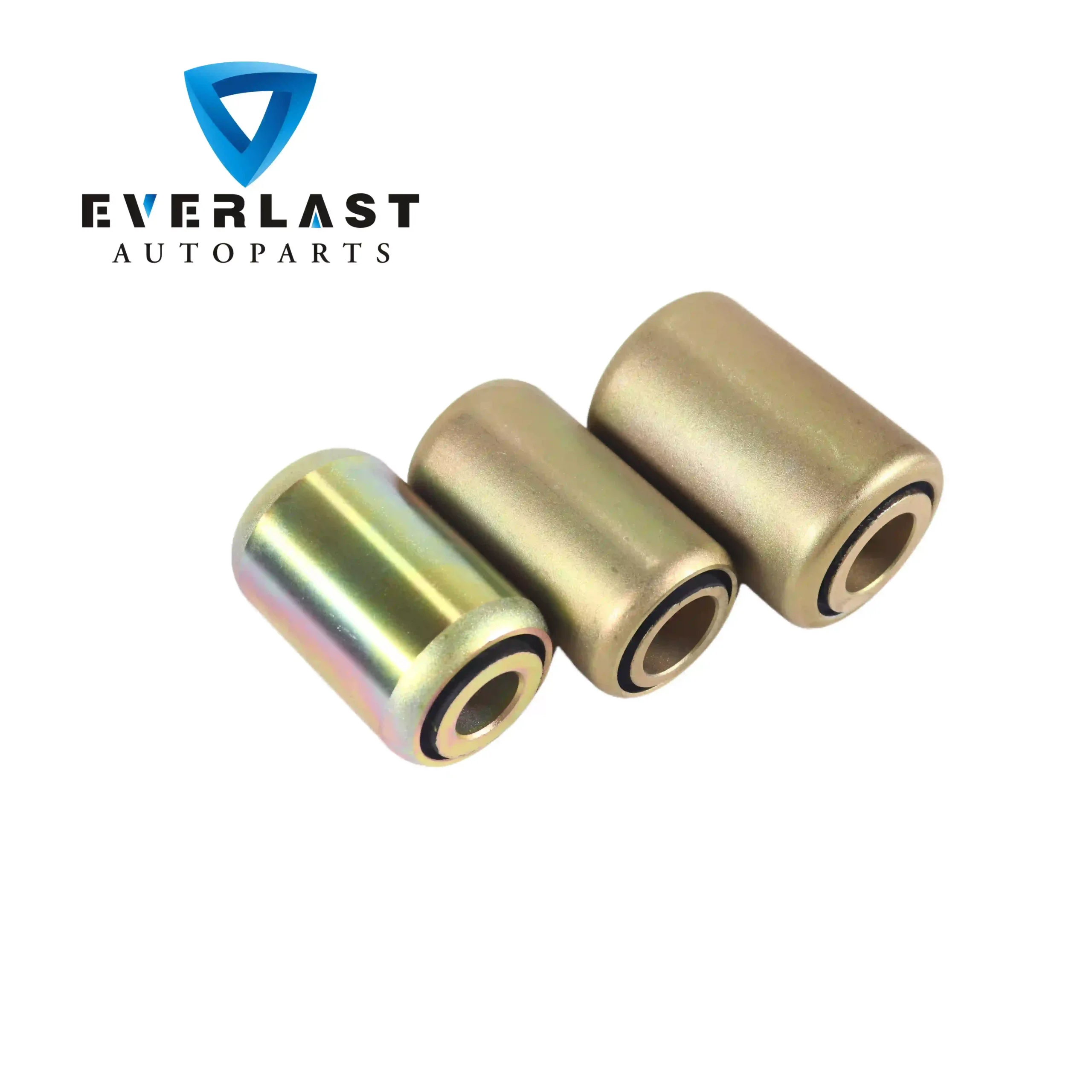

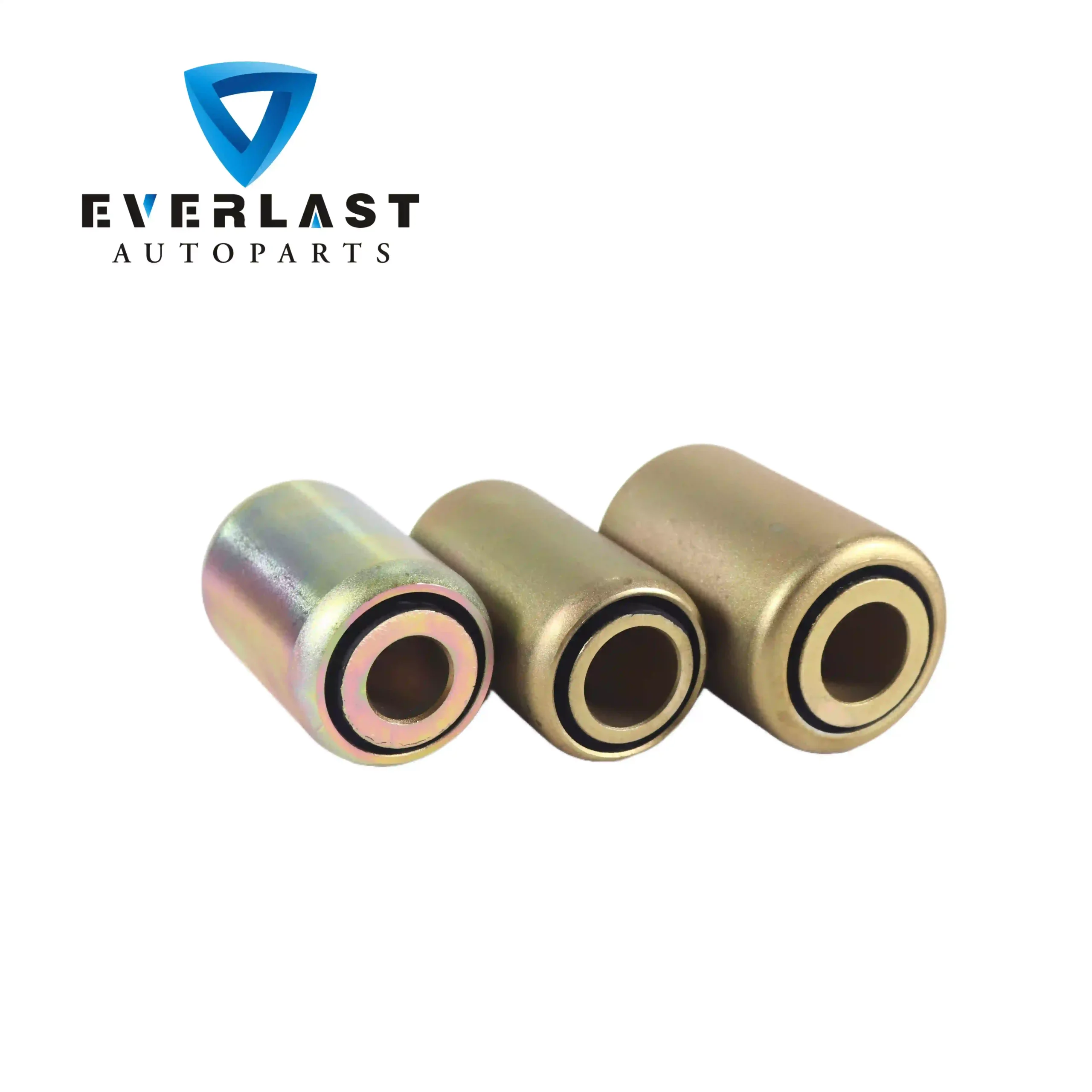

Bushes in car suspension

1. Common structure: metal + rubber + metal

2. Composed of inner and outer metal tubes and a rubber layer bonded together through a vulcanization process

3. Color: metal color

4. Engraved content: customized engraving according to customer requirements

Description

Model: trailing arm bushing

Specification: composite rubber bushing

Material: rubber + metal

Currently, the “axial-radial composite bonded rubber bushings” (collectively referred to in the industry as trailing arm bushings or support arm bushings) are the most common type used in European light/medium commercial vehicles (rear axles of VW Crafter, MAN TGE, Mercedes Sprinter, and Ford Transit).

The main composite rubber bushing models available on the market are as follows:

1) 2E0511415/2E0598611, applicable to VW Crafter 2F/MAN TGE models

2) 0610559AA, applicable to Mercedes Sprinter VS30 models

3) 2133529, applicable to rear axles of Ford Transit V363

4) 6C04969, applicable to Renault Master X62

5) 05114155AA, applicable to Fiat Ducato / Peugeot Boxer

The above models account for 80% of the sales in the European after-sales market. Molds with an “outer diameter of φ55-62 mm / inner diameter of φ22-25 mm / height of 70-80 mm” can cover all these models.

These rubber bushings feature a structure of outer framework + rubber body + inner core, and are completed through a bonding process.

Application position: front end of the rear axle trailing arm/guide arm, press-fitted with the main bracket of the subframe, bearing longitudinal braking force, lateral cornering force, and torsional return torque.

Common failures:

Rubber tearing (stress concentration at the roots of grooves) → when the crack reaches ≥10 mm after 120,000 km of mileage, replacement is mandatory;

Debonding between inner tube and rubber → in cold regions, the adhesive layer becomes brittle at a low temperature of -40℃, resulting in a “clanking” metal impact sound;

Outer tube rusting → in environments with snow-melting salt, rust spreads rapidly after the electrophoresis layer in the groove is damaged.

When the above failures occur, the bushing needs to be replaced as soon as possible.

.webp)

-scaled.webp)