Introduction

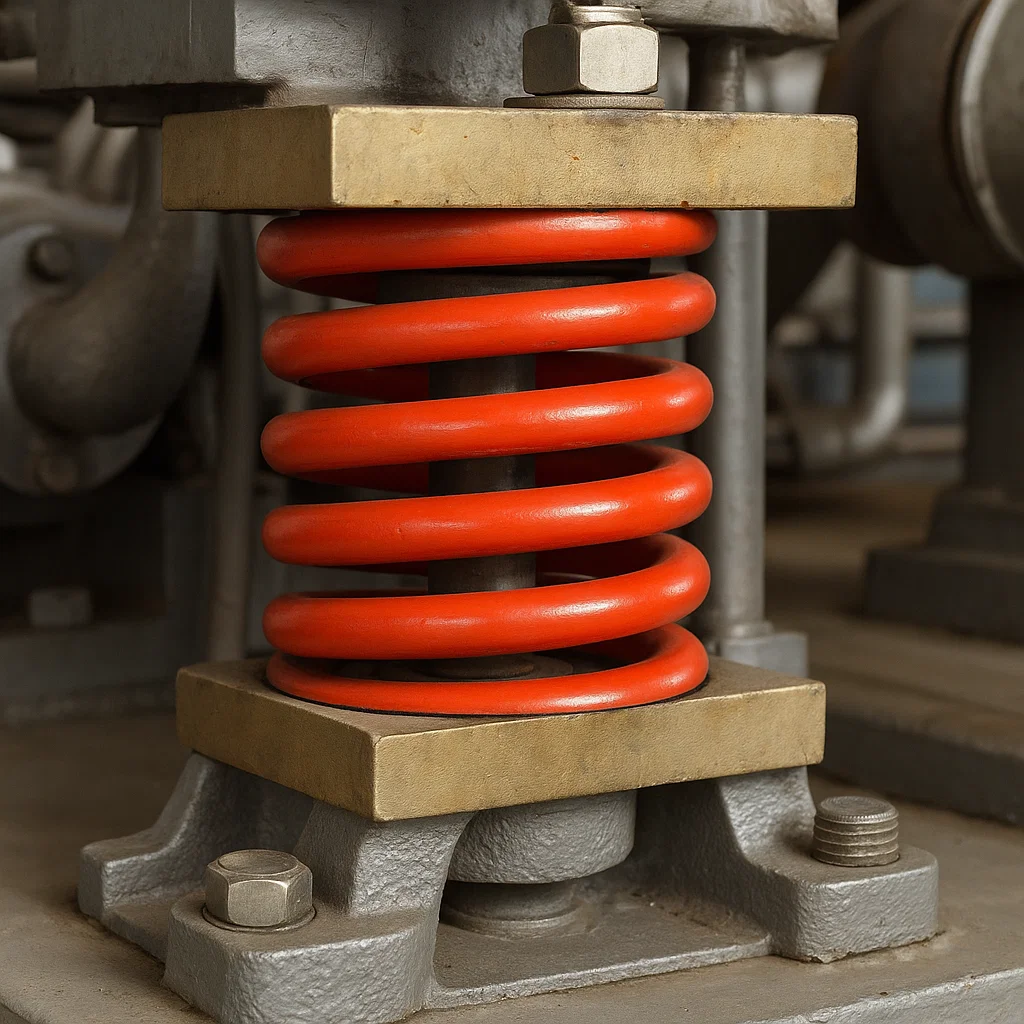

Industrial machinery operates under intense and continuous loads, often generating significant vibration and mechanical shock. To ensure operational stability, extend equipment life, and protect sensitive components, a reliable suspension element is essential. This is where coil springs play a critical role — offering superior vibration control, shock absorption, and load support across a wide range of industrial applications.

Why Coil Springs Are Essential in Industrial Equipment

Coil springs, also known as helical springs, are widely used in press machines, crushers, conveyors, loaders, and other heavy-duty equipment. Their robust design and energy storage capability allow them to absorb, store, and release mechanical energy efficiently during equipment operation.

Key benefits include:

- Excellent Vibration Damping – Reduces oscillation and prevents damage to machinery and structures.

- High Energy Absorption – Handles heavy impact loads and sudden shocks effectively.

- Consistent Performance Under Stress – Maintains load-carrying capability through millions of compression cycles.

- Compact Design – Offers high deflection and load capacity in limited installation spaces.

How Coil Springs Improve Vibration Control

Industrial environments often involve high-speed, repetitive motion that generates continuous vibration. Excessive vibration can lead to fatigue failure, loosened fasteners, and reduced accuracy in precision machinery.

Coil springs act as mechanical dampers, absorbing these vibrations before they transfer to the machine’s frame or foundation. This not only protects components but also improves operating precision and reduces noise, creating a more stable and efficient production environment.

Shock Absorption and Equipment Protection

Heavy industrial machinery is frequently exposed to impact forces from load changes, mechanical strokes, or material handling. Coil springs absorb these sudden shocks by compressing under stress and then gradually releasing stored energy.

This mechanism protects:

- Bearings and joints from impact fatigue

- Machine frames from cracking or distortion

- Operators from excessive vibration exposure

The result is longer equipment lifespan, fewer maintenance interruptions, and improved workplace safety.

Material Quality and Heat Treatment Process

The performance of coil springs largely depends on material selection and precise manufacturing. We produce industrial coil springs using premium spring steel such as 60Si2MnA, 50CrVA, or SUP9, ensuring optimal mechanical strength and elasticity.

Every spring undergoes:

- Heat treatment for enhanced fatigue resistance

- Shot peening to increase surface strength

- Load testing to verify compression and rebound performance

- Protective coating or painting for corrosion resistance in humid or outdoor conditions

These processes guarantee reliable function even under continuous vibration and high load cycles.

Customization for Different Industrial Applications

Every industrial machine operates under unique load conditions and environmental challenges. That’s why we offer customized coil spring solutions tailored to your requirements.

Options include:

- Variable wire diameters and spring rates

- Different end types (closed, ground, or open)

- Coatings such as phosphate, zinc, or epoxy paint

- Custom sizes for OEM or replacement use

Our engineering team works closely with clients to design springs that deliver maximum performance and service life in specific machinery environments.

Conclusion

For modern industrial operations, coil springs are a fundamental component of reliable vibration and shock control systems. Their ability to handle high loads, absorb shocks, and reduce vibration ensures the smooth and efficient running of machinery across multiple sectors.

By choosing high-quality, precision-engineered coil springs, you not only enhance machine performance but also reduce downtime, minimize maintenance costs, and extend the overall lifespan of your equipment.